Everything is in the bag

In the 1970s, the new disposable diaper provided a most welcome relief for families. The product was a staggering worldwide success that quickly generated orders, and therefore growth, on an unprecedented scale for Optima. An increasing number of machines were waiting to be assembled and shipped to anxious customers. The pressure was on, but Optima also overcame this new challenge with expertise and flexibility.

As generations of young parents have discovered, changing diapers is something you have to learn – and so is diaper packaging. How do you get a soft, and therefore unstable, product into its designated container quickly, precisely, and as compactly as possible? How about as hygienically and cleanly as the sensitive area of use demands?

One of the decisive factors is the pressure used in the packaging process, an important aspect for ensuring maximum compression of the diapers without damaging them in the process. This innovative technology is called high-compression packaging, Optima remains the forerunner in this market today – with systems that can apply up to five metric tons of strength and handle up to 120 packages per minute. Efficient and flexible. After all, nobody wants to wait for diapers.

Expertise in bags

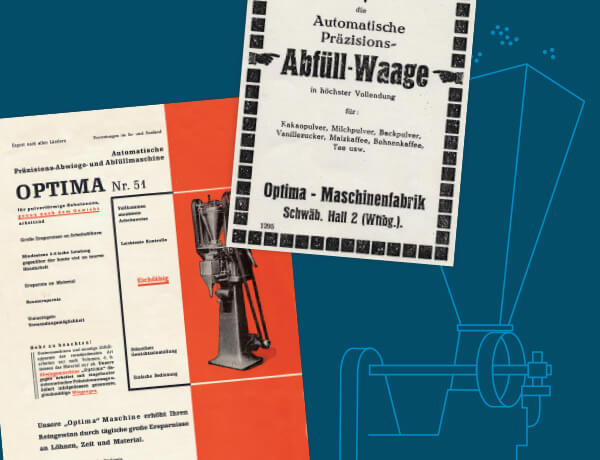

Optima initially gained important experience in handling soft – and therefore unstable – goods in a completely different context: packaging mass-produced bread in bags for the local corner stores that were still flourishing at the time. It is exactly this expertise that qualifies the up-and-coming company in Schwäbisch Hall, Germany for handling equally sensitive hygiene articles. These machines soon sell like hotcakes and become an important pillar for Optima.